Running the Railroad

16/06/25 11:33 Filed in: Operation

Planning to Operate

Operating on Tom Sullivan's Sheepscot & Sandy River layout

Model railroad operation extends the life of a layout by keeping it interesting long after construction is essentially complete. Operation turns the layout into a role playing game, providing rules for train movements that operators, or train crews, have to follow. Usually operation is set up to take advantage of the animation of model trains in order to add a dimension of realism to the modeled scenes.

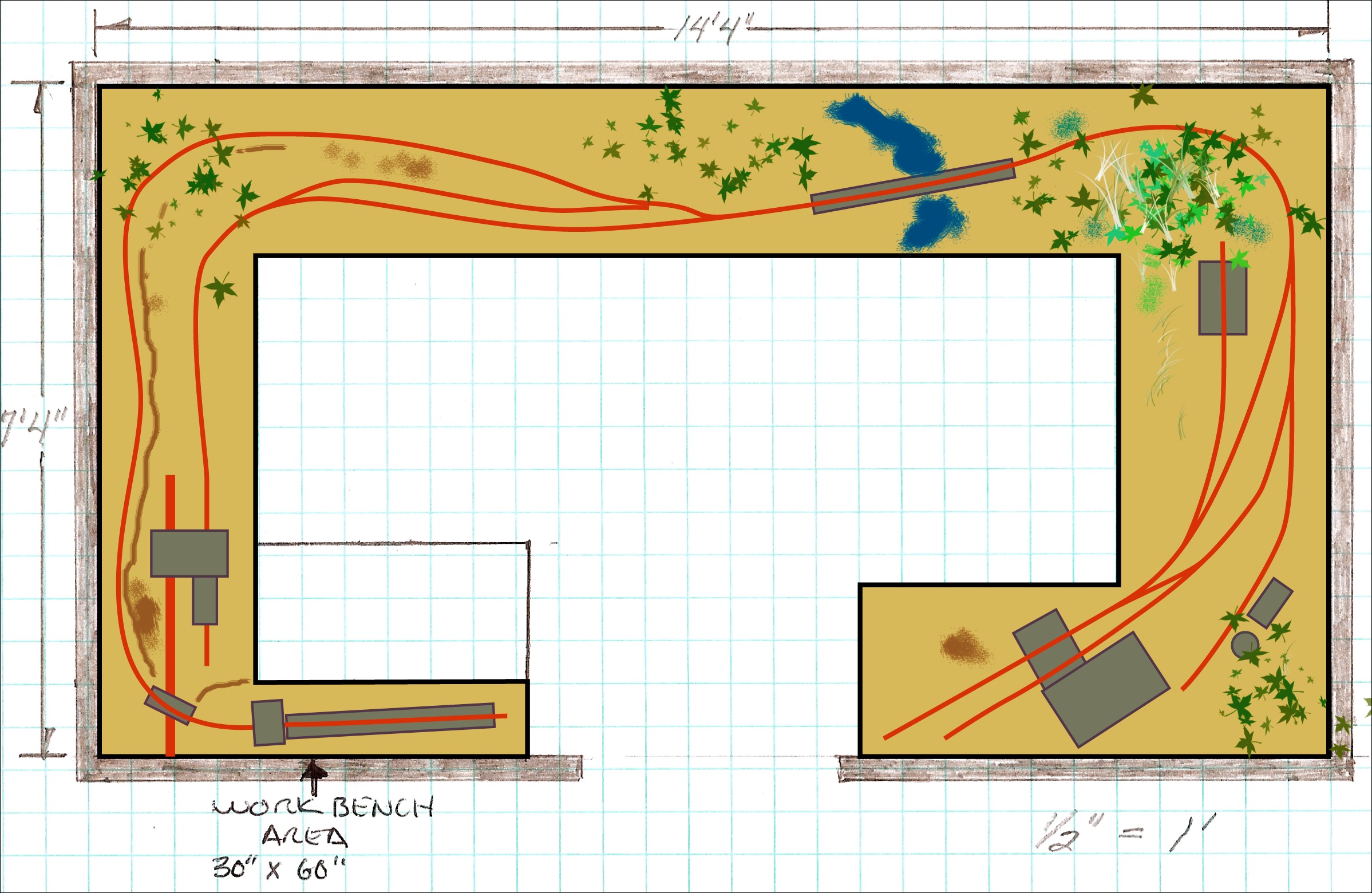

Preliminary track plan for Bill Davis

Operation has to be a priority in the planning phase of a model railroad in order for all the parts to add up to a realistic whole. A certain setting, theme, era, and operation need to be in mind as track is planned and scenes are developed. Usually a model railroad depicts a common carrier that cycles traffic onto and off of the layout from an implied national rail network.

Riverton Lime's industrial narrow gauge

On an industrial narrow gauge traffic still circulates around the layout but it is captive within the system. Freight is loaded at one scene on the layout, then unloaded at another. It can be a challenge to find historical information that provides insight as to what kind of equipment small industrial railroad operations used and how they were integrated into the workflows of the industries they served. Every operation was unique and many were temporary, not receiving much attention from railfans.

Barry Cott's examination of industrial narrow gauge operation

In order to put together an operating scheme that depicts a small soapstone operation in the Blue Ridge foothills of central Virgina, I began by studying Barry J. Cott’s Primer for Narrow Gauge and Short Line Operations. Barry makes no mention of soapstone in his primer, but he does explain how to operate a captive system where the entire railroad serves just one industry and all the loading and unloading cycles take place within the confines of the layout.

Operations on the Buckingham Branch Railroad in Beaverdam, Virginia

If a model railroader is planning to depict a common carrier operation on his layout it would probably mean that the railroad needs to run as a profitable transportation company. That would impact the track layout because rail service would need to be provided efficiently. On a common carrier layout, the railroad runs for its own best interest. The layout operates for the sake of the railroad itself. On the other hand, a private industrial railroad runs for the sake of the industry being served. There may be less of a priority on efficiency and more priority on accommodating the need for moving material and products in a way that reduces inventory and cost. The train crews use the railroad to run the industry.

Preparing to operate on my layout

'Model Railroad' or 'Layout'?

17/02/24 05:28 Filed in: Plan/Design

A distinction without a difference?

When I was in grade school I went through a wide range of hobbies in rapid succession. My mother was an art teacher and my father taught mechanical drafting and photography, so they were more supportive of my whims that involved making things. Model ships then model airplanes then model cars. Eventually I showed an interest in model trains and my parents allowed me space and helped with construction of a layout.

The setting and theme of a model railroad are prototype based

Back then, I was intent on building a model railroad while my parents thought a layout would better suit my needs. In the June 1971 Railroad Model Craftsman, Bill Livingston's article about his On30 Venango Valley Railway explores the difference between the two. As Bill sees it, the setting for a model railroad exists on maps. A geographic place in a particular timeframe. The theme of a model railroad can be developed by studying historic publications, trade journals, and taking rail fan trips.

The setting and theme of a layout are more about look and feel

The setting and theme of a layout are more about atmosphere. The setting is the room the layout occupies, and the theme is what the trains appear to be doing and how they are doing it. Bill sites the writing of Lin Moody and the preservation work of Ellis Atwood for providing him the inspiration for building an On30 layout. Personally, I might credit the writing of Garth Groff, H. Reid and Archie Robertson about the Nelson & Albemarle Railroad for providing a story around which a layout could be built.

Blocking together a scene with a hand painted backdrop and hand laid track

I would like my layout's setting to give a visitor the impression that the layout is hand made. I hand painted my backdrop, I hand laid my track. That motif will extend through construction of scenery and structures and even the locomotives and rolling stock. As Bill pointed out in his article, On30 is particularly well suited for hand made modeling. 30 inch gauge was never particularly popular among American railroads, so a 30 inch gauge layout seems to lack a priority on precisely depicting a prototype.

Switching cars at the mill is very similar in On30 as it is in any other scale or gauge

I would like my layout's theme to give a visitor the impression that I am interested in operation. Operation, with its high priority on functionality, is far more common on model railroads than layouts. Many excellent model railroads featuring operation are being built right now, and I am interested in following their progress. But I am often dismayed to find out how few model railroaders understand that operation is possible on narrow gauge layouts. It is different, but the basics of car forwarding and train management are the same.

Renderings do a better job of depicting the desired effect than mechanical drawings

Layout building, as my parents suspected, suits me. I like being able to interpret the historic facts and transfer them onto a project that is more creative and unique. A lot of creative thought goes into developing a scheme for operating my layout as well. The system should generate work for crews that complements the atmosphere and mood I am after.

Full Mock-Up Mode

05/12/23 09:17 Filed in: Plan/Design

Planning for extensions

Discussing my layout with Brian had led to the conclusion that, while construction was still in the early stages, accommodations needed to be made for extending the layout into three rooms again.

A new trackplan for the stone cutting and mill area was drawn up.

The plan showed the long back track exiting the layout room through the hole in the backdrop.

Track and roadbed was pulled up far enough to build a curve that would allow the track to go through the hole.

A cardboard pattern was made for cutting new roadbed and sub-roadbed.

A cardboard pattern was also made for the revised mill trackage.

The revised plan for this section of the layout showed the dust mill in this location. The old slate mill from my JRD On30 module was a stand-in to give an indication of what that would be like. I got the impression that the old locomotive service track was going to have to move closer to the aisle.

In the opposite corner of the layout where I had just flipped the subroadbed to divert tracks into the shop next door, I cut a cardboard pattern. A new turnout would divert traffic to a fiddle yard in the shop or allow continuous running.

Discussions and Decisions

21/11/23 09:36 Filed in: Plan/Design

The route forward

A few years had passed since I removed the Winwood and Piedmont sections of my layout. That simplified the project and made it all fit in one room. Construction on the three room layout had stalled for years, and I found the one room version of the layout much more approachable and easier to work on. But over time progess began to lag on the one room layout as well.My friend Brian Bond was in town and dropped by. We discussed my predicament. Brian was familiar with my layout when it ran in three rooms and had attended numerous operating sessions. From the standpoint of a visitor, the three room layout had a lot going for it. My shop is configured to accommodate a three room layout. Being in three rooms made the layout seem larger to an amazing degree. The flow of raw materials and finished products was more linear and obvious. The prospect of operating the three room version of the layout was far more appealing.

I had decided to reduce the size of the layout from three rooms to one immediately after turning over construction of the Railroad Display at The Quarry Gardens to Rail Tales of Charlottesville. While I was working on the Railroad Display, my personal layout sat dormant and was in my way. Years went by without ever hosting an operating session. I wondered why the layout needed to extend into three rooms when there was plenty of space in the layout room alone. Upon removal of the layout from my office and shop, those spaces immediately benefitted from the layout's absense.

By the time of Brian's visit, I had fond memories of when the layout ran in three rooms. The problem had been that the layout "intruded" on the office and shop spaces, which were never planned adequately to have a section of the layout in them. Brian's suggestion for my route forward was to plan to extend the layout into three rooms again. An excellent idea that is reflected in the Project post titled "Redirection Along the Wall."

Initial plans to extend the layout into three rooms again

Moving the Dust Mill

17/10/23 07:42 Filed in: Plan/Design

Reconfiguring operational elements

A primary ingredient in the mineral composition of soapstone in central Virginia is talc. Talc has a wide range of industrial applications and is a common component in the production processes of paint, paper, ceramics, and many other items. A dust mill is the facililty where a soapstone operation would crush and then mill the stone to a fine powder. The powder would be bagged and shipped to manufacturing plants.

Dust Mill ruins at Schuyler

The vast majority of soapstone quarries yield stone of a quality such that every bit of it is milled into talc. Central Virginia is one of very few places where the integrity of the soapstone cut from the quarries is high enough for it to be formed into dimensional stone for architectural applications. Even so, much of the stone from these same quarries is flawed in some way that prevents it being suitable for sawing and polishing to make finished pieces. A good deal of the high quality stone that makes it into the assembly plant will end up as breakage or cut-off scrap. So the quarries and the assembly plant are both generating raw material for the dust mill, adding operational interest for the train crews.

Mocking up a dust mill site

I am going to have a dust mill on my layout. I had to find a suitable location for it and suspected it could fit along the east wall so I grabbed a pile of structure pieces and parts to try to get an impression of what that would look like.

Layout track plan including dust mill

The current plan for the dust mill and assembly plant:

A: The track that extends into the office to serve the unmodeled Quarry No. 2

B: Gangsaw building

C: Assembly plant

D: Boilerhouse

E: Dust mill

F: Supply sheds and loading area

G: Talc bagging plant